STILL: Difference between revisions

From KIP Wiki

ā§¼kip-jumptonavigationā§½ā§¼kip-jumptosearchā§½

No edit summary |

|||

| Line 29: | Line 29: | ||

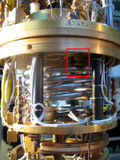

[[Image:Still_heater_new.jpg|right|thumb|120px|Picture of new still heater.]] |

[[Image:Still_heater_new.jpg|right|thumb|120px|Picture of new still heater.]] |

||

* CuNi-wire: d=??um, r=200{{O}}/m, R<sub>Still</sub>= 1.13{{O} |

* CuNi-wire: d=??um, r=200{{O}}/m, R<sub>Still</sub>= 1.13 k{{O}} |

||

* The heater is build up by N=100 twists of the wire wrapped around the former copper heater-body. GE-varnish was used to fix the wire and each layer. To protect the heating wires cigarette paper was added between each layer and at the end. Finally the we used dental floss wrapped around the cigarette paper as top layer to fix an shield the wire. |

* The heater is build up by N=100 twists of the wire wrapped around the former copper heater-body. GE-varnish was used to fix the wire and each layer. To protect the heating wires cigarette paper was added between each layer and at the end. Finally the we used dental floss wrapped around the cigarette paper as top layer to fix an shield the wire. |

||

* A twisted pair of copper wires (d=??mm , R=??{{O}} lead from the solder connection at the upper side of the still to resistor beneath it. The copper wires are connected to the heating wire via a solder pad clued on the the top layer of cigarette paper. A textile tube is used to protect the twisted pair. |

* A twisted pair of copper wires (d=??mm , R=??{{O}} lead from the solder connection at the upper side of the still to resistor beneath it. The copper wires are connected to the heating wire via a solder pad clued on the the top layer of cigarette paper. A textile tube is used to protect the twisted pair. |

||

Revision as of 16:24, 3 January 2012

General Informations

- Volume: VStill=??? .

- Seven heat sinks are installed on the still. Details klick here

- Still-Shield

Still Heater

- Connection: BOX II X3:(1-4).

- RStill= 1.13 k, new heater installed November 2011.

- IStill= 3-5 mA, depending on required cooling power.

- The still heater is mounted on the lower side of the still and is shielded by a gold plated copper housing. The whole setup is attached to the still by a single screw and is positioned right in the center of the continuous heat exchanger. The wires are shielded by a textile tube and lead from the resistor via a fed-through at the still-flange to the 1K-pot.

New Still Heater

- CuNi-wire: d=??um, r=200/m, RStill= 1.13 k

- The heater is build up by N=100 twists of the wire wrapped around the former copper heater-body. GE-varnish was used to fix the wire and each layer. To protect the heating wires cigarette paper was added between each layer and at the end. Finally the we used dental floss wrapped around the cigarette paper as top layer to fix an shield the wire.

- A twisted pair of copper wires (d=??mm , R=?? lead from the solder connection at the upper side of the still to resistor beneath it. The copper wires are connected to the heating wire via a solder pad clued on the the top layer of cigarette paper. A textile tube is used to protect the twisted pair.

Old Still Heater

- Resistance of still heater : RStill=880. Based on the original SHE-manual it was supposed to be ~1k?

! removed November 2011, since it didn't work anymore. One resistance-foil was broken.

Still Shield

...